Jump to section

At Hannover Messe, visitors can see firsthand how companies can reduce errors and increase efficiency in complex operations by enabling production tracking with real-time production visibility alerts and analytics using Tulip apps and the ZeroKey Quantum RTLS™ platform.

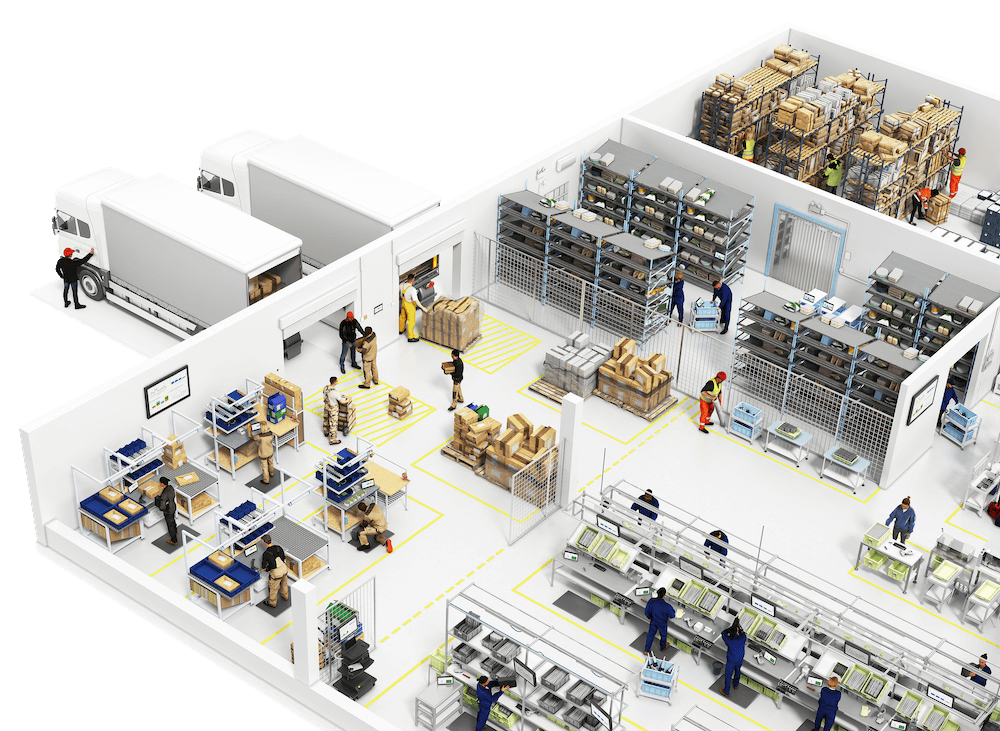

Knowing the exact location of materials and equipment within industrial environments is critical for monitoring inventory levels, cycle times, and understanding bottlenecks. Engineers often have to track a process to determine where bottlenecks and errors are occurring, and as operations scale, it can be difficult to monitor every cell and station.

With a range of trackable tags suitable for diverse applications, ZeroKey sensors track the 3D real-time location of assets, processes, goods, and personnel critical to modern business with unprecedented resolution. Tulip’s platform enables engineers to build triggers and apps using the real-time data from ZeroKey to perform time studies and track jobs.

Frontline workers can wear a ZeroKey sensor to help error-proof their workflows in real-time. A Tulip app can provide a visual indicator if a work order or piece of equipment is placed in the wrong spot. By deploying this integrated solution, engineers are able to assess the quality and safety of their entire operation in real-time with powerful analytics based on live data.

Tulip and ZeroKey are committed to enabling continuous improvement for engineers by providing them with the tools they need to build solutions that are agile and scalable. At the opening of the Tulip Experience Center, the Tulip team was able to build the ZeroKey technology demonstration in just a few hours. See the demonstration in action at the Tulip Experience Center or at Hannover Messe 2022.

See why manufacturers trust Tulip to help drive digital transformation

See how a connected system of apps and sensors enable real-time visibility into your operations.