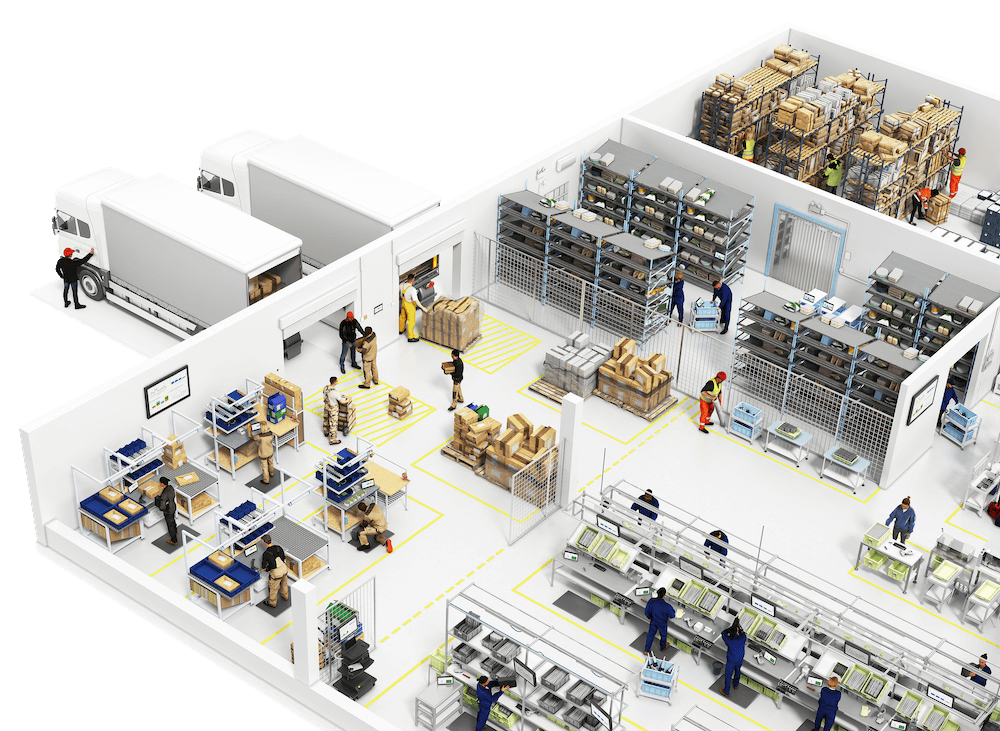

It’s more critical than ever for manufacturers to adopt a system that can balance flexibility and scalability. That system needs to be able to complete two things simultaneously: empower those closest to the operations to solve problems quickly and build upon existing infrastructure to expand use cases, thus future-proofing operations against disruptions and unexpected changes in the future.

At IMTS 2022, Tulip will showcase the capabilities of the Frontline Operations Platform. Through a series of interactive demonstrations featuring real-world use cases, we will illustrate how an operations platform can help you improve your processes and solve some of the most pressing challenges in operations: error-proofing processes and boosting productivity with guided workflows, capturing and analyzing real-time data, and continuously improving operations.

Use Case: Complex Assembly and Inspection

A workflow that includes data collection equips operators, not hinders them. Contrary to the popular misconception that technology will replace humans, when properly implemented, technology can augment people’s abilities and free them up to focus on more impactful tasks, such as problem-solving.

Assembly and inspection apps can streamline workflows, eliminate mistakes, boost productivity and capture actionable data to empower decision-making. By providing detailed work instructions and a dynamic workflow, these apps enable workers to move faster and more confidently by streamlining their daily work and empowering problem solving right on the shop floor.

Tulip will feature two interactive experiences for this use case: an Edge MC assembly and DeWalt clamp assembly.

Demo: Edge MC Assembly

The operator is guided through the final assembly of Tulip’s Edge MC device, including verification of completeness.

Experience this demo if you are interested in:

Guided picking

Verification of final product quality

Anomaly detection for missing screws

Demo: DeWalt Clamp Assembly

The operator is guided through the final assembly of a DeWalt Trigger Clamp.

Try out this demo if you are interested in:

Guided picking

Dynamic workflow adaptation based on entered values

Actionable connections to ERP/MES

In-line assembly inspection and validation

Ease of variant/BOM management in App Editor with tables

Use Case: Agile App Editing

Changes are inevitable on your production line, whether in the form of new parts or new steps. Process engineers need to be able to quickly make changes to the existing processes and instructions and communicate those changes effectively to operators.

Tulip’s no-code app editor empowers those closest to the operations to make changes to the existing process and quickly implement them, minimizing disruptions and defects.

Demo: Word Clock Inspection feat. ProGlove

The demo recreates a challenging situation that requires a change in the process: a concerning number of assemblies ship out without their power supply. This needs to be addressed ASAP. With a no-code app editor, it’s easy to add a step to verify the final weight before completion to ensure quality and completeness.

Check out this demo if you are interested in:

The Tulip App Editor

Guided picking

Device connectivity for assembly validation

Agile response to manufacturing issues

No-code app development

Use Case: Machine Monitoring

Complete visibility of your operations is a powerful capability: manufacturers can dig into the data and its source to gain insights into bottlenecks, gaps, and more. Machine monitoring empowers you to drive accurate and timely decision-making without the need to rely upon vendors or integrators.

This demo shows how you can utilize a live and continuously updating machine monitoring dashboard to understand how your plant is performing.

Demo: Soldering Safety App + Machine Monitoring Dashboard with DMG Mori

This demo will show you how data is gathered and updated continuously to a live dashboard, which is also interactive and can be examined in more detail. Using Tulip’s Analog Machine Monitoring capability, the demo will walk you through the process of utilizing operational data to inform decision-making.

Stop by and experience this demo if you are interested in:

Digital Machine Monitoring cases, especially when not co-located with the machine/data source

Analog Machine Monitoring capability

Check-out and validation processes (incl. e-sig)

‘Mobile’ (i.e. not at a PC) capability

All Tulip’s demos will be located at our booth #134748, East Hall Level 3. If you share one of the challenges above, don’t hesitate to stop by during the show or reserve your demo time here to skip the wait.

Experience Tulip's Frontline Operations Platform at IMTS 2022

Learn how Tulip can help streamline your operations and augment your workers' abilities